|

ChinaStoneConeCrusherDirectory company,

|

Gold Index: 11090

Vibrating screen and Ultrasonic vibration transducer and generator

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Vibrating screen and Ultrasonic vibration transducer and generator

&n

Vibrating screen and Ultrasonic vibration transducer and generator

Specifications:

Type: CCH-33100

Frequency(khz): 33

Resonance Impedance(Ω) 20-40

Static Capacity (pF)±10%: 5000

Input power(w):100

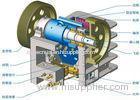

Ultrasonic vibration transducer is one kind of piezoelectric transducers.

It comprises a radiation head, an electrode, cap, prestressed bolt, piezoelectric chip

and an insulating tube. The ultrasonic vibration transducer is widely used

in vibrating screen equipment factory (so now the vibrating equipment can have both the mechanical

and ultrasonic vibration). It separates materials into finer detail, more uniform and more efficient,

which is especially suitable for fine-screening materials.

Ultrasonic vibrating screen is the ultrasonic generator and vibrating screen together new products,

the principle is to 220 v, 50 hz or 110 v, 60 hz power can be converted into high frequency electric energy

of 18 to 40 KHZ, reoccupy perfectly on the sieve box ultrasonic vibrator head

will be high frequency electric energy into mechanical energy,

make the invisible to the naked eye of supersonic vibration sieve surface,

makes the ultra micro powder accept huge ultrasonic acceleration,

the material on the surface of the screen always stay suspended state,

and thus dampen adhesion, friction, pancake, wedging, such as screen blocking factors,

thus achieve the purpose of efficient screening and network,

makes the ultra micro powder screening for easy. Especially suitable for high quality,

fine powder of users.

Feature

Improve the low density of the powder in the gravity settling pancake

(powder contact with the advantage of network),the slippage effect

improve the high density of metal in the front-end ports retention or wedging,

improving the adhesion effect of electrostatic powder,

thus improve the screening efficiency and quality of screening.

Application

1. To achieve high accuracy, high mesh screening at the same time,

the control of a narrow particle size range.

2. Can be used single layer and multilayer.

3. Screen selfcleaning function: greater than 500 mesh sieve, no mesh plug,

no attenuation screening efficiency.

4. Solve the strong adsorption, easy to reunite, electrostatic, high precision, high density,

high light specific gravity and other screening problem.

5. Screening accuracy can improve the 1-70%, yield can increase 0.5 to 10 times.

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

ChinaStoneConeCrusherDirectory company, [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)